|

We are intent on bringing the latest technology

and materials into equipment for people with disabilities.

Our goal is to work with each person's individual disability and deliver

products that they need.

3D Modelling Services

|

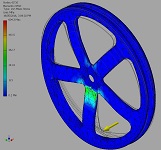

We can supply 3D Modelling Services to develop custom made

assistive technology that is personalised to the unique needs of

each individual. The models created can be stress tested in

simulations to ensure that finished part has the required

strength. We also have significant experience actualising models

into real world equipment that can be used, including

manufacturing in plastics, carbon fibre, aluminium, stainless

steel, brass and silver. We have experience with the strengths

and limitations of various manufacturing techniques and and can

design parts with specific materials and manufacturing it can be

brittle |

I I

Stress Analysis Model |

3D Printing

Plastics

We have experience printing in ABS, Nylon, TPU, Acrylic and

Metallic Plastic. Each plastic has different strengths and

weaknesses that need to be matched to the intended application.

ABS is a rigid plastic that will flex slightly before breaking.

It is the plastic used in Lego and is a robust and reliable

plastic. It is the plastic we use in our custom phone holders on

wheelchairs. Nylon is a strong and flexible plastic that has a

wider printing window then ABS. When printed thin it can be

flexible like a hinge. When printed thick it is strong and

ridged. TPU is a flexible rubber plastic that we can vary the

hardness by varying the density. Acrylic is a high detail

plastic although it can be brittle. Metallic Plastic is printed

with fine aluminium particles, which give it a metallic sparkle,

although it is stronger than ABS and Nylon it is also more

brittle. |

Phone Holder for a Wheelchair |

Brass Stylus Tip |

Metal

We have experienced printing in Brass, Aluminium and Stainless

Steel. The parts we printed in metals have been used in

custom-made stylus for head operated computer equipment.

|

CNC Machining

| With larger parts CNC machining is more

cost-effective than 3D printing, the parts can then be anodised

to any desired colour. We have machined and anodised many

complicated shapes, for example a 3 piece caster wheel assembly

for a prototype wheelchair. |

CNC Machining |

Composite Parts

| We have been developing Carbon Fibre

reinforced 3D printed parts that consist of an a custom ABS

honeycomb core wrapped in carbon fibre. This method of

instruction allows us to develop unique parts tailor-made for

the individual that are extremely light and strong. We have been

testing this manufacturing method with custom-made armrests for

power wheelchairs. The armrests are designed to correct hand

deformations by realigning the hand in an anatomical neutral

position. |

ABS & Carbon Fibre |

|